Heat Treatment of Nickel Aluminum Bronze Alloys

Many of the standard Nickel Aluminum Bronze Alloys are heat treated per their alloy standard. The heat treated alloys are as follows:

- C63000 ASTM B150 HR50 AMS 4640

- C95510 ASTM B505 AMS 4880

- C63020 ASTM B150 AMS 4590

- C95520 ASTM B505 AMS 4890

The reason for this is that heat treating these alloys can have many beneficial effects to the metal. They are as follows:

- Relieve internal stress

- Increase ductility

- Adjust tensile and hardness

- Improve wear resistance

- Reduce magnetic permeability

There are different methods of heat treating. Each with their own unique benefits and purposes.

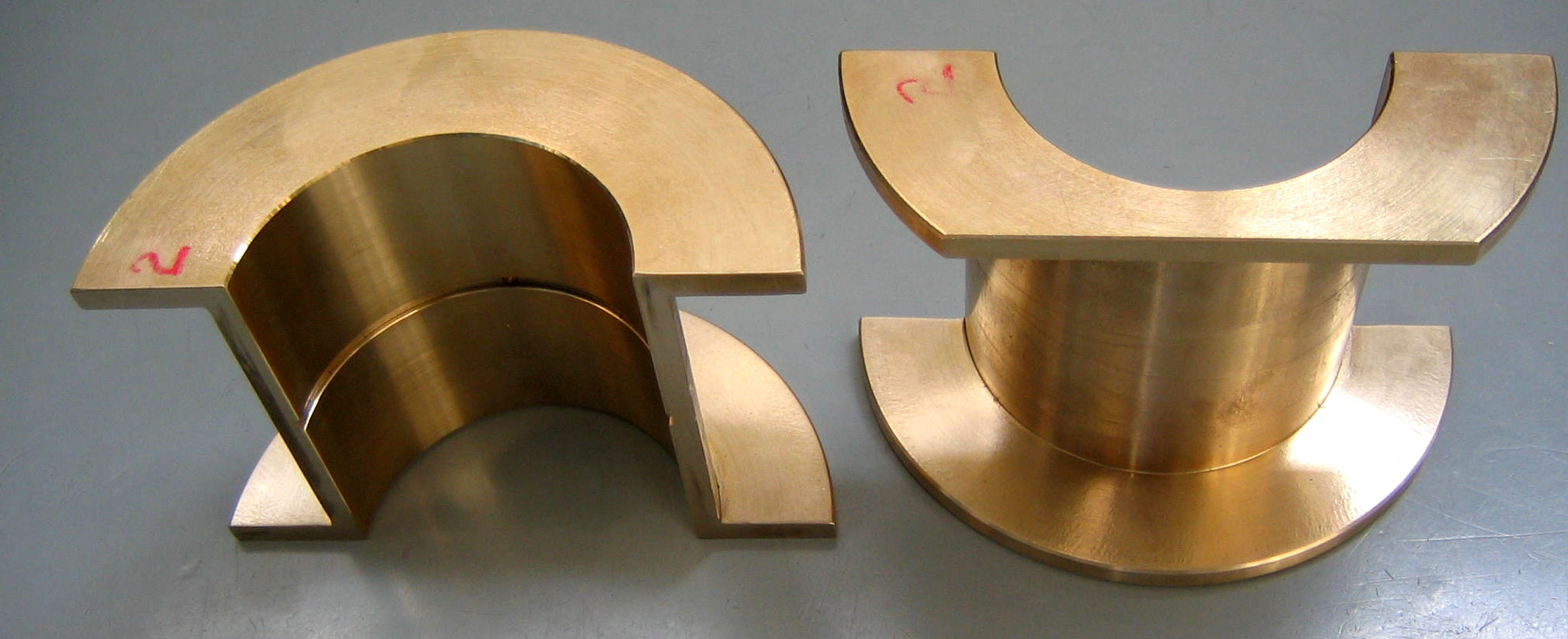

Stress Relieving

This type of heat treatment is used to relieve internal stress caused by cold working, rapid cooling, and/or machining. Stress relieving of Nickel Aluminum Bronze is done at lower temperatures than annealing. This is really useful when the Nickel Aluminum Bronze is being machined into thinner walled bushings, like those used in aircraft landing gears. As some Nickel Aluminum Bronze bar stock can have a tendency to spring after larger amounts of metal is removed. By having the bar stock stress relieved, it is less likely to spring out of tolerance after machining.

C63000 ASMT B150 AMS 4640 is stress relieved and cold drawn in sizes up to 3” diameter. Being that this alloy is used extensively in bushing applications, the stress relieving helps keep the close tolerance needed when machining the bushings.

Annealing

Generally this is done at a higher temperature than stress relieving. Annealing can cause a greater degree of microstructural change to the metal. Recrystallization will normally occur at temperatures above 1247° F.

Quenching and Tempering

Nickel Aluminum Bronze reacts similarly to alloyed tool steels in respect to heat treatment procedures. A martensitic phase is formed in the alloy when Nickel Aluminum Bronze is water quenched from elevated temperatures. Once quenched Nickel Aluminum Bronze Bars can be tempered to improve ductility while still retaining a high tensile and hardness.

In alloy C63000 TQ50 AMS 4640, this alloy is quenched hardened and temper annealed. C63000 bar stock above 3” diameter is heat treated this way. This gives this larger diameter greater tensile strength, improved hardness, at the same time while improving the ductility of the metal.

C95510 is a cast alternative to C63000. In this alloy heat treatment is used to give this cast alloy similar mechanical properties to the extruded version. This alloy is also quench hardened and temper annealed.

Heat treatment can be a useful technique used to both relieve stress and improve mechanical properties in Nickel Aluminum Bronze Alloys.

To learn more about our standard Nickel Aluminum Bronze Alloys, follow the links below:

C63000 AMS 4640 Nickel Aluminum Bronze