Cast Bronze Alloys -Operating Temperatures and Hardness Ratings

Cast bronze alloys come in a number of different varieties each with their own advantages and disadvantages. The way that Bronze Mills are able to offer different properties is through the addition of specific elements in varied amounts to the alloy composition. For example, the addition of Lead (Pb) to a bronze alloy helps increase the machinability as well as give it inherent bearing qualities. The addition of Aluminum (Al) to a bronze alloy can increase its load bearing capacity as well as provide corrosion resistance to sea water.

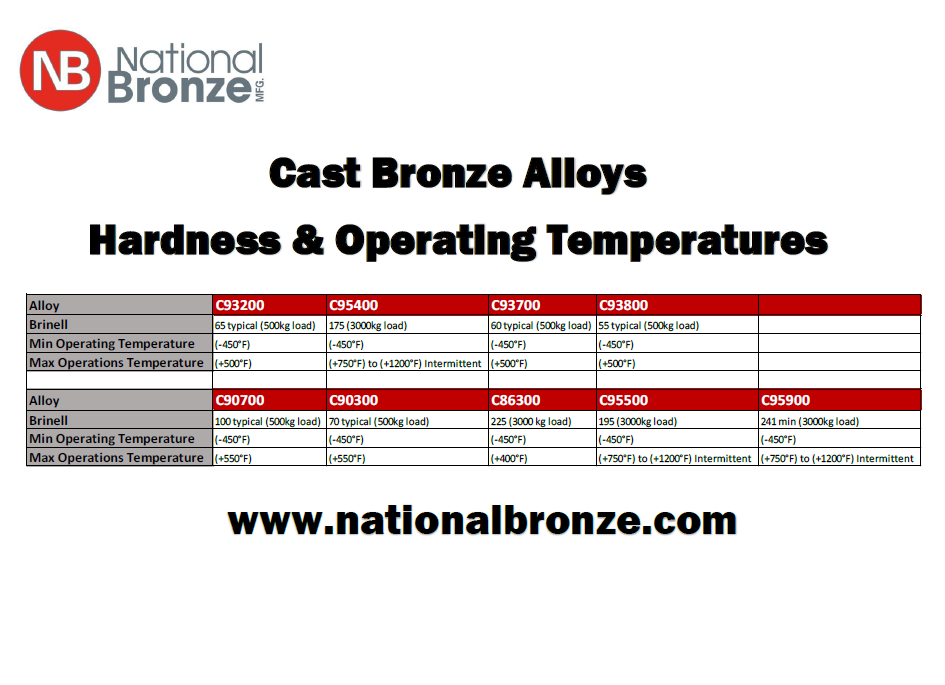

There are many advantageous properties that can be achieved based on the bronze alloys elemental composition. Some properties that engineers may be interested in when designing the ideal alloy for a bronze bearing application are operating temperature and hardness. Depending on the application, bronze bearings may be exposed to extreme temperatures. When designing the ideal alloy for specific applications, it’s critical to know the minimum and maximum operating temperature for specific bronze alloy. We have listed a few of the more popular bronze alloys below, along with their operating temperatures and hardness.

| Alloy | C93200 | C95400 | C93700 | C93800 | |

| Brinell | 65 typical (500kg load) | 175 (3000kg load) | 60 typical (500kg load) | 55 typical (500kg load) | |

| Min Operating Temperature | (-450°F) | (-450°F) | (-450°F) | (-450°F) | |

| Max Operations Temperature | (+500°F) | (+750°F) to (+1200°F) Intermittent | (+500°F) | (+500°F) | |

| Alloy | C90700 | C90300 | C86300 | C95500 | C95900 |

| Brinell | 100 typical (500kg load) | 70 typical (500kg load) | 225 (3000 kg load) | 195 (3000kg load) | 241 min (3000kg load) |

| Min Operating Temperature | (-450°F) | (-450°F) | (-450°F) | (-450°F) | (-450°F) |

| Max Operations Temperature | (+550°F) | (+550°F) | (+400°F) | (+750°F) to (+1200°F) Intermittent | (+750°F) to (+1200°F) Intermittent |

In addition to the above information, we’ve created a downloadable chart to use when determining the most suitable bronze alloy for your bearing application.